Broco® Underwater EasyTouch® Eletrodes de solda

27 de junho de 2017

Broco® Underwater BR-20 Welding Stinger – Alicate Porta Eletrodo.

27 de junho de 2017Broco® Underwater SofTouch® Eletrodes de Solda Aço e Inox

– Proprietary formula key to reliability, ease of use

– Certifiable welds with less labor costs

Broco's flux enhancing proprietary formulation, BroCote™, is the secret behind the reliability and ease of operation of the SofTouch electrode. BroCote makes this electrode particularly impervious to water penetration and denigration and ensures certifiable underwater weld quality with less labor cost and time consumption.

SofTouch electrodes are used for on-site repairs in many applications where steel must be joined underwater according to code specifications. SofTouch welds consistently meet or exceed AWS D3.6-98 specifications for Type B welds, the American Welding Society's standard for certifying underwater welds. SofTouch is designed to pass all AWS test requirements, including radiograph, bends and hardness and is the wet welding electrode welding engineers and divers prefer.

Since 1989, SofTouch electrodes have been specified in the U.S. Navy's Ships Husbandry Manual Chapter 11, “Underwater Wet and Dry Chamber Welding.” U.S. and Navy diving commands, shipyards, and contractors use SofTouch for repairs and maintenance on Naval vessels worldwide.

SofTouch electrodes are available in various sizes and alloys for both mild steel and stainless. SofTouch mild steel electrodes are available in 1/8 inch, 5/32 inch and 3/16 inch diameters. Stainless electrodes are sold in 1/8 inch and 5/32 inch sizes.

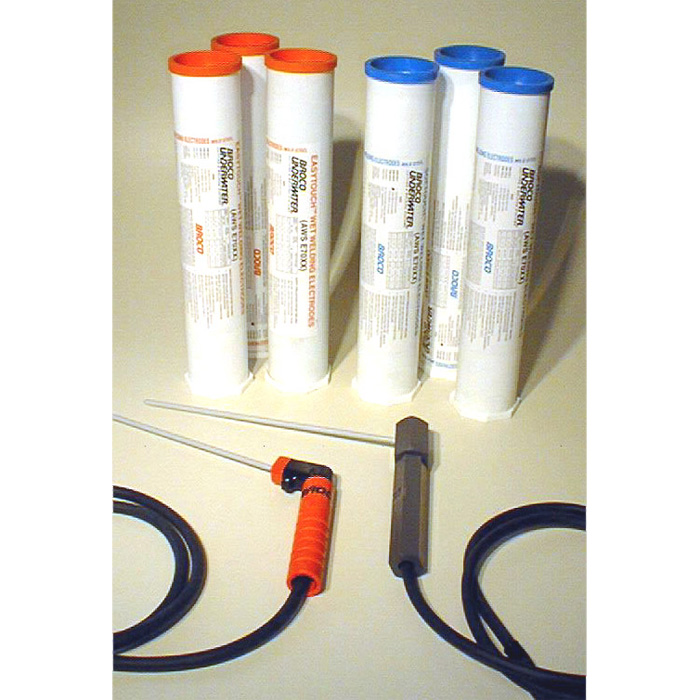

SofTouch wet welding electrodes are sealed in a Mil-Spec foil pouch to prevent contamination. The electrodes are then packaged in a rigid resealable plastic tube which provides maximum protection. The color-coded end cap denotes mild or stainless steel electrodes. Operating guidelines are printed on the label.

SofTouch® Stainless Steel

SofTouch® Stainless Steel

UW-CS-1(2,3) SofTouch® Premium Wet Welding Electrodes, 8 lb. tube

– 1/8″ 95 electrodes

– 5/32″ 69 electrodes

– 3/16″ 48 electrodes

UW-SS-1(2) SoftTouch® Stainless Wet Welding Electrodes, 8 lb. tube

– 1/8″ 95 electrodes

– 5/32″ 69 electrodes